By adopting lightweight materials for the bus body, we have realized the powerful driving and long-distance cruising of EV vehicles.

Use of high-strength composite material (CFRP)

High-strength composite material CFRP (Carbon Fiber High-Strength Composite Material) is used for part of the bus body. Lightweight (1/5 of steel) and high strength (5 times stronger than steel).

Furthermore, it has the characteristics of low thermal expansion, high temperature resistance and corrosion resistance.

スUsing stainless steel chassis

STALA350 stainless steel is used for the chassis of the body. It has the advantages of high strength, light weight, fatigue resistance and corrosion resistance.

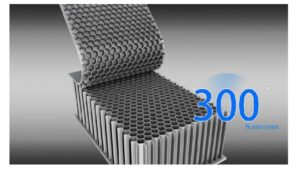

Flooring with aluminium honeycomb material

We have adopted a floor material that applies an aluminum honeycomb structure. It has lightweight, high node strength, high compressive strength, high tensile strength, high shock absorption, high soundproofing and high temperature resistance, providing a comfortable in-vehicle environment.

Using GFRP

The front hatch is made of GFRP (Glass Fibre High-Strength Composite Material) to reduce weight.The front hatch does not require special tools and can be opened and closed easily, reducing the burden during maintenance.